Contact us

0769-85338950

TEL:0769-85338950

FAX:0769-85328216

EMAIL:lionpower@126.com

ADD:No.15, Jinxia huancun East Road, Chang'an Town, Dongguan City, Guangdong Province

Automated instrumentation is composed of a number of automated components and is an automated technical tool with more complete functions. It generally has several functions at the same time, such as measurement, display, recording or measurement, control, alarm, etc. The automation instrument itself is a system and a subsystem of the entire automation system. Automated instrument is a kind of "information machine" whose main function is the conversion of information form, converting input signal into output signal. The signal can be expressed in the time domain or the frequency domain, and the transmission of the signal can be adjusted into a continuous analog quantity or an intermittent digital quantity.

Market scale of automation instrumentation industry

There is a big gap in the overall technical level between domestic and foreign. There is a big gap between the overall technical level and product quality of my country's industrial automation instrument industry and the advanced level of foreign countries, and the core technology is mainly imported from abroad. Industrial automation instrument products need to mature gradually through continuous trial and error and improvement, and the technology accumulation cycle is long. In 2017, the market size of my country's automation instrumentation industry was 237.016 billion yuan, and by 2018 it increased to 245.786 billion yuan, a growth rate of 3.70%. In 2019, the total industry market size was 251.193 billion yuan, a year-on-year increase of 2.2%.

With China’s in-depth implementation of the strategy of a manufacturing powerhouse and accelerating the process of digitization, networking, and intelligence in the industrial sector, the country attaches great importance to the development of this industry, "Intelligent Manufacturing Development Plan (2016-2020)", "Enhancement of Manufacturing Core Competitiveness III Annual Action Plan (2018-2020)”, “High-end Intelligent Remanufacturing Action Plan (2018-2020)”, “5G+Industrial Internet” 512 Project Promotion Plan, “About Further Promoting the First (Set) Major Technology "Notice on the Pilot Work of Equipment Insurance Compensation Mechanism" and other industrial plans and policy measures have been introduced successively, providing strong support for the further improvement of the development level of the industry. From the perspective of long-term market trends, the country continues to deepen the implementation of smart manufacturing and green manufacturing projects, accelerate the transformation of manufacturing into smart, green, and service-oriented industries, and increase technological transformation and upgrading in downstream industries, environmental protection standards, equipment updates, and localization of key components. Work intensity, the demand for intelligent equipment and technical services will continue to rise.

According to the research report of China Research and Puhua, ``2020-2025 Automated Instrumentation Market Status Survey and Supply and Demand Pattern Analysis and Forecast Report'' statistical analysis shows:

【1】. Cost composition of automated instrumentation

The upstream industry of instrumentation includes a variety of electronic components and materials, and among the electronic components is the development of sensors. Although my country's own research on materials and electronic components has increased in recent years, it can basically achieve self-sufficiency. At the same time, the introduction of high-end sensor technology has also caused the development of the upstream industry and market changes dominated by sensors in my country. Instrumentation has less influence.

However, due to the country's emphasis on smart sensors, my country has made breakthroughs in key sensor technologies, and wireless sensors have also begun to enter the process of research and development. As a large-scale company cannot gain a foothold, small companies can only rely on traditional technology to earn shares. Through the development in recent years, relying on the support of policies, the drive of state-owned enterprises and the combination of new industries such as the Internet, my country's sensor industry has successfully pushed the development of the sensor industry into a golden age. As the upstream industry of instrumentation, although the impact is small, it also shows a good development market.

【2】. Development status of upstream industry

Current status of electronic components industry

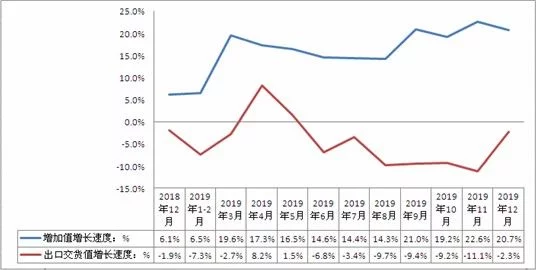

With the rapid development of my country's electronic information technology, my country's electronic component industry has developed rapidly, and the production of electronic components has entered a new level. In December 2019, the added value of the electronic components and electronic special materials manufacturing industry increased by 20.7% year-on-year, and the export delivery value decreased by 2.3% year-on-year. Among the main products, the output of electronic components increased by 26.9% year-on-year. In 2019, the operating income of the electronic component and electronic special materials manufacturing industry increased by 0.3% year-on-year, and the profit decreased by 2.1% year-on-year.

Chart: The monthly growth rate of the added value and export delivery value of the electronic component industry from December 2018 to December 2019

Source: Ministry of Industry and Information Technology

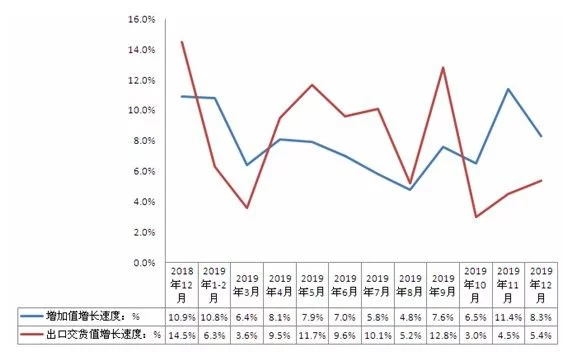

In December 2019, the added value of the electronic device manufacturing industry increased by 8.3% year-on-year, and the export delivery value increased by 5.4% year-on-year. Among the main products, the output of integrated circuits increased by 30% year-on-year. In 2019, the operating income of the electronic device manufacturing industry increased by 9.4% year-on-year, and profits fell by 21.6% year-on-year.

Chart: The monthly growth rate of the added value and export delivery value of the electronic device industry from December 2018 to December 2019

Source: Ministry of Industry and Information Technology

In 2016, the production of my country's electronic component industry rose steadily. The annual production of electronic components was 3745.5 billion, a year-on-year increase of 9.3%. In 2019, my country's output of electronic components was 6752.4 billion, a year-on-year increase of 26.9%.

Chart: 2010-2019 my country's electronic component production trend

Source: Ministry of Industry and Information Technology, National Bureau of Statistics

With the development of my country's electronic information economy and the continuous advancement of electronic technology, the development of the electronic component industry is gradually developing in the direction of modernization and scale. With the gradual expansion of the application scope of my country's electronic components market, more and more companies are participating in the electronic components industry, which promotes the continuous prosperity of my country's electronic components market. However, due to the late development of electronic components in China, my country's electronic components market is relatively chaotic, and the added value of enterprise products is low, which is not conducive to the development of electronic component enterprises.

Chart: my country's major electronic components companies

Source: Compiled by China Research Institute of Puhua Industry

【3】. Development trend of upstream industry in 2020-2025

(1) Chip and miniaturization

The current CPU manufacturing process is still far from the theoretical minimum size of transistors, and it has not reached the physical limit. For the future technological development of semiconductor manufacturing, Moore’s Law believes that even if the industry no longer depends on the reduction of device size and the expansion of wafer area To reduce costs, semiconductor products can integrate different types of technologies in a system package, moving towards a diversified integration direction; following Moore’s Law, it is believed that smaller transistors can be integrated on the chip to reduce the critical size. In short, the component industry may provide specific package-level or system-level products through chip, miniaturization, and integration of more digital and analog technologies.

(2) Development towards integrated modularization

Since passive electronic component manufacturing processes differ greatly in materials and technology, they have been used in the form of discrete components for a long time. Although people have been making a series of efforts in the miniaturization of chip components, their development is relatively slow compared with the high integration of semiconductor devices. In recent years, due to technological breakthroughs such as low-temperature co-fired ceramics (LTCC), passive integration technology has entered the stage of practical and industrialization, and has become a technological commanding height that has attracted much attention.

(3) Multifunctional

As the functions of new electronic products continue to increase, the requirements for the functions of chip components are becoming more and more diverse. Although in terms of quantity, the chipization rate of electronic components has reached more than 70%, but the development is very uneven. Some components are difficult to chip due to process, structure, and materials. For example, a magnetic bead component with an inductance structure does not function as an inductor, but is anti-electromagnetic interference. At present, the chip-type magnetic bead component has become the largest type of chip inductance component. The design and materials of these new components are new problems faced by electronic components.

(4) Non-toxic, harmless, safe and environmentally friendly development

In the manufacturing process of electronic components, some toxic materials are often used, such as cleaning agents, solvents, solders, and some raw materials. Some finished electronic components sometimes contain toxic substances, such as mercury, lead, and cadmium. Heavy metals. With the strengthening of people's awareness of safety and environmental protection, countries all over the world are paying great attention to safety and environmental protection electronic components. Many countries have now legislated to prohibit the use of these toxic and harmful substances. Under such a background, green and environmentally friendly electronic component manufacturing has emerged. The development of green, safe and environmentally friendly electronic components directly determines the market share and development prospects of the product, thus putting forward higher target requirements for the electronic component manufacturing industry.

【4】 the impact of upstream industries on the automation instrumentation industry

The development of the upstream industry will affect the development of the automation instrumentation industry. When the output growth rate of the upstream industry decreases significantly and the price rises, the supply of raw materials in the automation instrumentation industry will be insufficient, which has a great impact on the production of the automation instrumentation industry.

To learn more about the professional analysis of the automation instrumentation industry, please pay attention to the research report of China Research and Puhua, "2020-2025 Automation Instrumentation Market Status Survey and Supply and Demand Pattern Analysis and Forecast Report"